As soon as a warehouse strikes past a number of hundred orders per day, accuracy challenges cease being remoted errors and start turning into systemic price leaks.

At decrease volumes, occasional choosing or packing errors could appear manageable. As success scales, nevertheless, those self same errors quietly erode margins. In high-volume warehouses and fast-growing 3PL environments, accuracy is now not simply an operational metric- it instantly impacts buyer retention, service prices, and long-term progress.

This shift is why many warehouse leaders are rethinking how accuracy is constructed into their workflows as an alternative of relying solely on guide checks and human vigilance.

The Hidden Price of Achievement Errors at Scale

Most success groups are aware of points similar to mispicks, incorrect bundle weights, and supply disputes. What is commonly underestimated is how shortly these issues compound as order quantity will increase.

Frequent challenges embrace:

- Selecting errors throughout peak demand or seasonal spikes

- Incorrect bundle weights triggering service changes

- Restricted proof throughout buyer supply disputes

- Bottlenecks throughout order consolidation and packing

Even a small error price, when utilized throughout 1000’s of orders, can translate into vital annual losses as soon as returns, reshipments, labor prices, and chargebacks are factored in.

Why Accuracy Breaks Down as Quantity Will increase

Handbook success workflows rely closely on particular person focus and consistency. As order quantity rises, pickers are required to make lots of of speedy selections per shift, usually below time strain and with comparable SKUs saved shut collectively.

Fatigue, operational complexity, and velocity expectations naturally enhance the chance of error- even amongst skilled groups. In lots of circumstances, the difficulty isn’t coaching or effort, however the absence of methods that cut back ambiguity at crucial determination factors.

From Handbook Processes to System-Guided Achievement

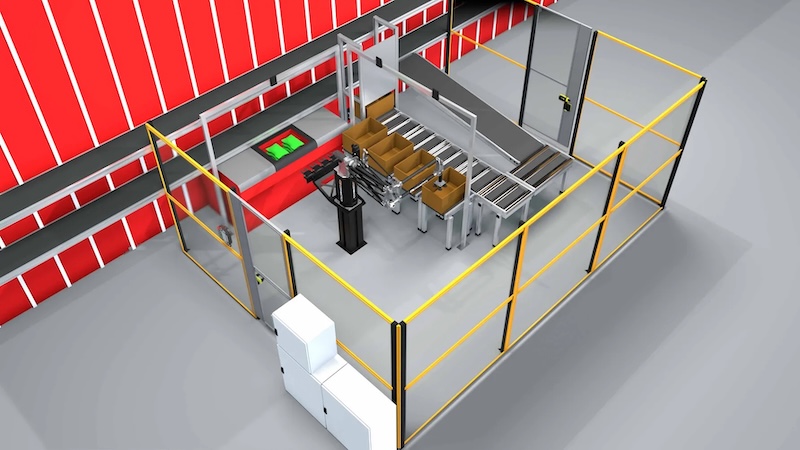

To deal with these challenges, main success operations are adopting applied sciences that visually information actions, robotically confirm steps, and seize proof all through the success course of.

Quite than asking groups to work sooner, these methods are designed to make the proper motion simpler to carry out. Many high-volume operations now use pick-to-light fulfillment systems to scale back guesswork throughout choosing and consolidation, bettering consistency throughout shifts and groups.

How Accuracy Applied sciences Help the Workflow

Fashionable success platforms deal with accuracy challenges at a number of phases of warehouse operations. These applied sciences could be deployed individually or mixed, relying on the place errors most regularly happen.

Platforms similar to Vendor {Hardware} assist these accuracy-focused workflows by providing modular instruments that combine with current warehouse operations moderately than changing them outright.

Key capabilities embrace:

- Skublox Choose-to-Mild and Put-to-Mild methods that visually information choosing and order consolidation

- 4D Sensible Scales that robotically seize weight and dimension knowledge to scale back transport discrepancies

- PACKCAM, a video-based packing verification resolution that data the packing course of to offer visible proof and assist resolve disputes

Collectively, these instruments assist warehouses enhance accuracy whereas sustaining operational flexibility.

Bettering Accuracy With out Rebuilding the Warehouse

One of the frequent misconceptions about success expertise is that it requires changing current methods. In follow, many accuracy-focused options combine instantly with present warehouse workflows and could be deployed incrementally.

This method permits operations to handle particular downside areas—similar to high-error SKUs or packing stations- with out disrupting the broader warehouse atmosphere.

Why Verification and Information Matter Extra Than Ever

As success volumes enhance, the significance of verifiable knowledge grows alongside them. Correct weight data, dimension knowledge, and visible packing proof present operational readability and accountability.

This knowledge helps warehouses:

- Resolve disputes extra effectively

- Scale back chargebacks and service penalties

- Enhance accountability throughout shifts and groups

- Construct belief with enterprise prospects

For operations transport at scale, verification is now not optional- it’s a safeguard towards pointless price and friction.

A Smarter Path to Scalable Achievement

Probably the most profitable warehouses as we speak usually are not merely working sooner. They’re working extra persistently.

By embedding accuracy instantly into success workflows, operations can scale with confidence whereas defending margins and buyer relationships. Accuracy turns into a system-level functionality moderately than a continuing guide problem.