Roboworx, a robotic area service group, has launched superior synthetic intelligence-powered predictive analytics capabilities for its Robotic Service Supervisor (RSM) software program.

This new predictive analytics functionality strikes robotic upkeep from a reactive “break-fix” mannequin to a extra proactive, data-driven method, decreasing downtime, extending the robotic’s helpful life, and accelerating promised return on funding.

The brand new RSM AI makes use of machine studying to research historic service knowledge and real-time telemetry, permitting Roboworx to anticipate mechanical failures earlier than they happen and streamline communication between technicians and purchasers.

By combining service historical past with odometry knowledge comparable to cycles accomplished, miles traveled (for autonomous cell robots or AMRs), or items produced, RSM AI identifies patterns in element put on or utilization.

Jeff Pittelkow, managing director at Roboworx, says: “With predictive analytics, we will now flag particular elements for substitute primarily based on utilization ranges throughout totally different fashions.

“When a technician heads to a web site, the system tells them precisely what’s prone to fail subsequent. This permits us to anticipate points as an alternative of simply reacting to them, which in flip helps hold the robots working at peak effectivity regardless of the duty.”

Simplified summaries for purchasers and techs

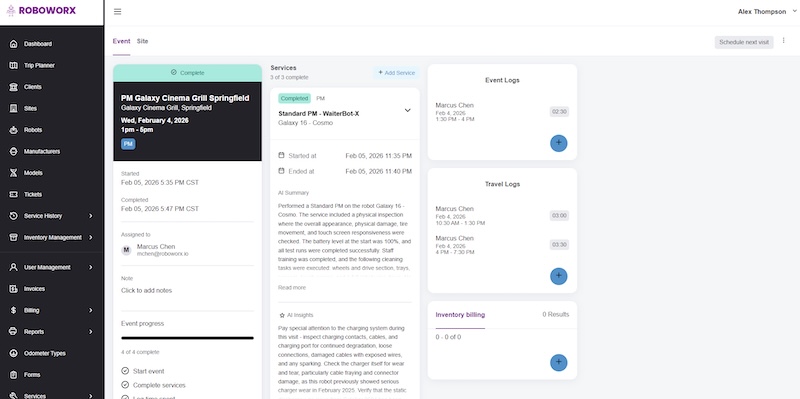

Past predictive modeling, RSM AI additionally solves the “knowledge fatigue” widespread in area service. The AI-powered system routinely converts technical types and checklists into easy-to-read summaries much like a health care provider’s after-visit transient.

For instance, facility managers can view a concise, plain-language summation of their robotic’s “well being” through a shopper portal whereas robotic technicians know the precise server historical past, together with recurring points particular to every robotic mannequin, lengthy earlier than they arrive on web site.

Whereas RSM was publicly launched in 2025, Roboworx has been coaching the end-to-end robotic upkeep software program over the previous 5 years as the corporate extends its data of serving robots and elements throughout a number of industries comparable to warehouse, cleansing, supply, and meals service industries.

Along with the brand new AI-powered predictive analytics, RSM contains:

- A single, unified view of preventative upkeep, break/repair occasions, outages and repair historical past at each the robotic and web site stage, together with earlier than and after pictures of labor carried out

- A complete scheduling system to make sure skilled robotic technicians are dispatched and managed successfully and effectively for periodic preventative upkeep in addition to on-call break/repair

- Full shopper entry to those information and knowledge, enabling full administration visibility into area service operations of their robots

The mixing of AI builds upon an already sturdy platform that has helped firms:

- Cut back break/repair calls by as much as 93 % when used for preventative upkeep

- Shorten restore occasions by as much as 50 % by higher technician preparation

Chris McNelis, VP of operations at Roboworx, says: “As robotic know-how grows extra advanced, RSM AI has already confirmed to be a useful device to make sure our specialists ship the simplest care earlier than purchasers even know they want it.

“Technicians don’t have to alter how they work as a result of the AI handles the reporting, permitting them to give attention to the {hardware} whereas maintaining the shopper absolutely knowledgeable.”

RSM is included at no further cost for all Roboworx companions, making certain that robotic OEMs and end-users can maximize the ROI and lifespan of their automation investments.