Good factories run on real-time information, linked programs, and automatic workflows. HR ought to function with the identical stage of precision. In spite of everything, when manufacturing traces are digital however onboarding packets and payroll documentation are nonetheless guide, errors and delays observe.

Under are seven HR processes sensible factories ought to modernize to scale back friction and enhance operational efficiency.

1. Worker Onboarding

Manufacturing hiring typically strikes rapidly, particularly throughout enlargement or seasonal demand spikes. Paper packets, guide verification, and scattered security varieties gradual time-to-productivity.

Digital onboarding platforms centralize tax varieties, direct deposit particulars, security acknowledgments, and certification data. So, new hires full documentation earlier than their first shift, giving supervisors extra time to concentrate on coaching and tools readiness.

Organizations investing in digital worker experiences in smart factories see stronger engagement and sooner ramp-up occasions. Sooner onboarding instantly reduces extra time stress and staffing gaps on the ground.

2. Payroll Processing

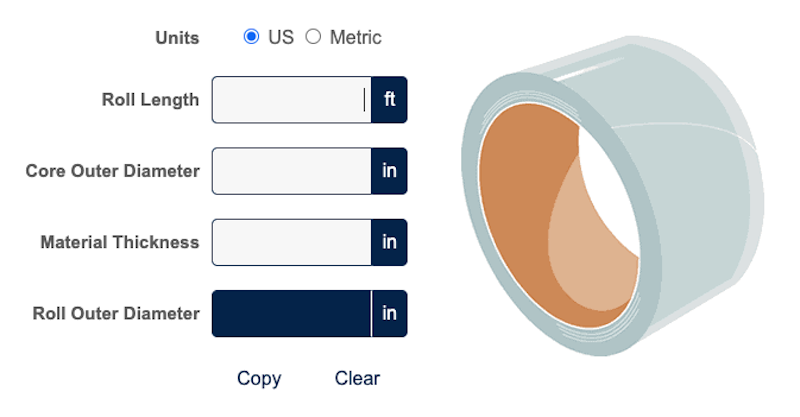

Good factories typically take care of rotating shifts, extra time tiers, and incentive pay. Managing that complexity manually will increase the chance of calculation errors and recordkeeping points.

Whereas built-in payroll programs calculate wages, HR groups nonetheless want correct, compliant documentation for each pay cycle. Many operations depend on instruments to rapidly generate skilled pay data that mirror variable hours and pay buildings.

As an illustration, FormPros permits HR groups to create pay stubs on-line rapidly and securely, serving to guarantee correct and compliant payroll documentation for every pay cycle.

Clear payroll processing builds belief. When workers can simply overview correct pay particulars, confidence will increase.

3. Time and Attendance Monitoring

Good factories rely on exact scheduling to keep away from downtime and bottlenecks. Guide time clocks and spreadsheet monitoring restrict visibility and delay decision-making.

Digital time and attendance programs sync with badge entry, scheduling instruments, and manufacturing dashboards. Supervisors acquire real-time perception into staffing ranges, absentee traits, and extra time publicity.

HR leaders more and more prioritize workforce analytics and automation. Information-driven workforce administration ranks among the many high strategic initiatives. Clear labor information helps you handle prices whereas sustaining output targets.

4. Coaching and Certification Administration

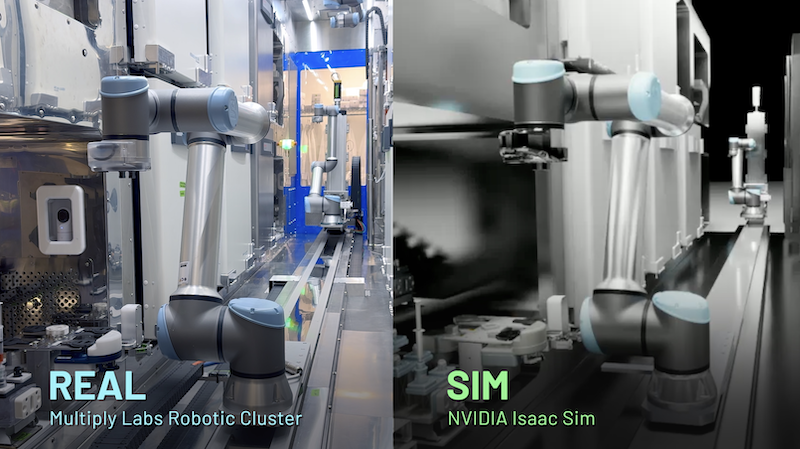

Superior robotics and automatic equipment require present certifications and ongoing security coaching. Guide monitoring programs make it straightforward to overlook renewal deadlines.

Digitized coaching platforms retailer credentials, tools {qualifications}, and security acknowledgments in centralized dashboards. Automated alerts notify managers earlier than certifications expire, lowering compliance threat.

Digital workforce instruments are important in superior manufacturing. Actual-time abilities visibility permits managers to assign certified workers with out guesswork, bettering security and manufacturing continuity.

5. Efficiency Evaluations and Expertise Monitoring

Annual evaluations alone don’t mirror the tempo of a linked manufacturing facility flooring. Efficiency information already exists in high quality reviews, output metrics, and security dashboards.

Digitized efficiency administration programs combine operational information into structured evaluations. Managers can align measurable productiveness outcomes with profession improvement plans.

Related programs enhance transparency and decision-making throughout manufacturing operations. Aligning HR efficiency instruments with manufacturing information strengthens accountability and inside mobility.

6. Advantages Enrollment and Administration

Manufacturing amenities typically handle a whole lot of workers throughout a number of shifts. Paper-based advantages enrollment will increase administrative pressure and confusion.

Digital advantages platforms permit workers to check plan choices, replace dependents, and overview protection particulars from any system. Self-service entry reduces repetitive HR inquiries and improves general readability.

Improved advantages communication helps retention in aggressive labor markets. Environment friendly administration additionally frees HR groups to concentrate on strategic workforce initiatives.

7. Compliance Documentation and Recordkeeping

Producers function beneath strict labor, tax, and office security rules. Lacking or incomplete documentation can lead to fines and operational disruption.

Digitized doc administration programs securely retailer I-9s, W-4s, OSHA logs, and payroll data in searchable databases. Function-based entry protects delicate info whereas protecting data audit-ready.

Organized compliance programs scale back stress throughout inspections. Sooner retrieval occasions additionally reduce disruptions throughout regulatory evaluations.

Why Good Factories Want Digitized HR Duties

Good factories thrive on linked programs and real-time insights. HR processes should help the identical stage of effectivity to maintain operations operating easily.

Digitizing HR duties corresponding to onboarding, payroll documentation, compliance monitoring, and coaching strengthens workforce transparency and reduces avoidable errors. Good factories that modernize HR duties create a stronger operational basis.

In the event you thought this text was useful, ensure you take a look at a few of our different posts.