AnyMile is designed to deal with cargo drone complexities. Supply: Mitsubishi Electrical

As robotics and synthetic intelligence proceed to advance, even longtime machine builders are pursuing digital transformation. Mitsubishi Electrical United States, or MEUS, stated it’s creating software-as-a-service platforms, data-driven instruments, and AI-powered programs bridging the bodily and digital worlds.

One instance of MEUS’s digital-first improvements is its AnyMile logistics software program to handle drone cargo operations. Zafer Sahinoglu, vice chairman and common supervisor of the Mitsubishi Electrical Innovation Middle, replied to questions from The Robotic Report concerning the firm‘s digital initiatives and air mobility operations.

Digitalization can assist companies of all sizes, with or with out AI

What are among the largest ache factors presently dealing with massive enterprises and small and midsize companies (SMBs) that digitalization can assist deal with?

Sahinoglu: Giant enterprises and SMBs face most of the identical structural challenges at the moment: workforce shortages, rising power and working prices, fragmented and siloed information, rising service-level expectations, and rising strain to function extra sustainably and constantly.

Digitalization helps deal with these challenges by bettering operational visibility and coordination throughout bodily belongings and workflows. When achieved accurately, it permits predictive upkeep, extra environment friendly use of assets, and automation of repetitive or high-friction processes.

Fairly than merely including dashboards, efficient digital programs combine sensing, connectivity, analytics, and governance instruments to assist higher operational choices. The result’s improved reliability, decreased waste, and organizations which might be higher ready to scale and adapt in a quickly evolving surroundings.

Whereas there was plenty of curiosity round AI in manufacturing recently, how has MEUS been working to assist with digital transformation? How a lot includes connectivity, simulation, and digital twins fairly than AI?

Sahinoglu: AI has an vital function to play, however in our expertise, many digital transformation efforts fail as a result of foundational components are ignored. At MEUS, we focus first on connectivity, information integrity, and system-level visibility, guaranteeing that bodily belongings might be reliably noticed and ruled in actual working circumstances.

Digital twins, connectivity layers, and standardized information fashions are sometimes extra impactful than AI alone, notably in industrial and logistics environments. These components create a dependable operational baseline that enables AI and superior analytics to be utilized safely and successfully.

In different phrases, AI delivers worth solely when it’s constructed on high of programs which might be already observable, dependable, and well-integrated.

How a lot information is sufficient, and the way do you assist customers decide what they want?

Sahinoglu: Extra information doesn’t mechanically translate into extra worth. The actual problem is knowing which information issues, why it issues, and the way it creates worth in a given operational context.

On the Innovation Center, we developed a “information worth canvas” to assist groups systematically assess the connection between information, choices, and outcomes. The framework evaluates what choices a system must assist, what uncertainties should be decreased, and which information sources meaningfully enhance reliability, effectivity, or compliance.

This strategy helps organizations keep away from over-collection and as a substitute concentrate on high-value, decision-relevant information. By aligning information technique with operational and enterprise targets, customers can construct programs which might be each easier and more cost effective.

AnyMile addresses cargo drone complexity

How sophisticated is drone cargo administration, and the way does AnyMile deal with it? How intently does Mitsubishi Electrical work with drone producers and repair suppliers?

Sahinoglu: Drone cargo complexity is rising quickly, notably as operations transfer from pilot applications to scaled deployments. At scale, complexity arises not simply from the autos themselves, however from the rising variety of assets and actions that should be coordinated earlier than, throughout, and after every mission.

This consists of fleet availability, airspace constraints, payload necessities, regulatory compliance, floor operations, exception dealing with, and post-mission reporting. AnyMile addresses this by serving as a mission-centric orchestration layer that manages the total lifecycle of drone operations.

We work intently with drone producers and repair suppliers to combine their platforms, guaranteeing that the system can adapt as automobile capabilities, operational fashions, and regulatory necessities evolve.

How a lot integration work and time are required to deploy AnyMile?

Sahinoglu: AnyMile is designed for fast deployment and minimal integration effort. The platform is already built-in with UTM [uncrewed traffic management] programs within the U.S., enabling airspace-aware operations from the outset.

We’re additionally actively engaged on EPIC system integration to assist seamless medical supply workflows and compliance with healthcare operational necessities.

From an operational standpoint, onboarding is deliberately light-weight. Registering a fleet of drones and configuring vertiports might be accomplished inside minutes, permitting operators to grow to be operationally prepared with out prolonged setup or system overhauls.

This modular integration strategy reduces deployment threat, accelerates time to worth, and permits clients to scale drone operations progressively as mission complexity and quantity enhance.

Mitsubishi Electrical analysis crosses {hardware} and software program

Do any of MEUS’s applied sciences apply to different robotics and automation? Do you collaborate with Mitsubishi Electrical’s {hardware} facet?

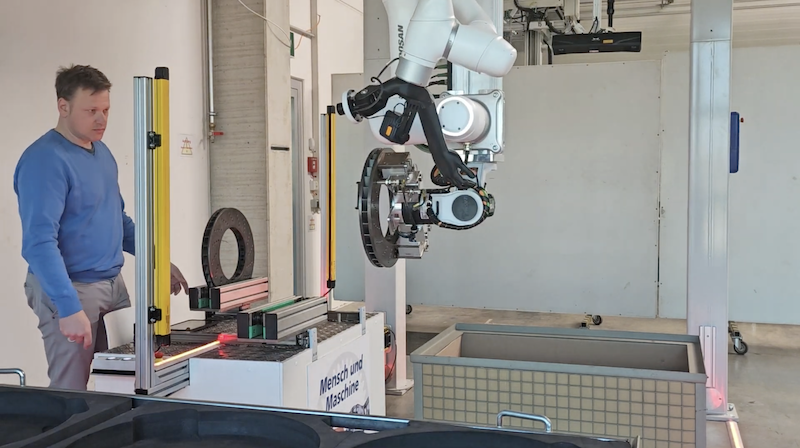

Sahinoglu: Sure. A core energy of MEUS’s strategy is the mixture of software program, information, and {hardware} to create system-level benefits throughout robotics and automation. Our software program platforms are designed to be broadly relevant throughout totally different courses of robotic and industrial programs, enabling coordination, observability, and governance past particular person gadgets.

Collaboration with Mitsubishi Electrical’s hardware-centric divisions is key to this technique. By aligning software program structure, information fashions, and {hardware} capabilities from the outset, we are able to ship built-in programs which might be extra dependable, scalable, and simpler to deploy in real-world environments.

This collaboration is additional strengthened via shut engagement with Mitsubishi Electrical Analysis Laboratories [MERL], whose analysis helps form the superior applied sciences embedded in MEUS’s next-generation options. Collectively, this built-in strategy creates a sturdy aggressive benefit that extends throughout a number of robotics and automation domains.

MERL headquarters in Cambridge, Mass. Supply: Mitsubishi Electrical

What are some ongoing challenges for software program and automation nonetheless to handle?

Sahinoglu: Key challenges embody integrating legacy infrastructure, guaranteeing cybersecurity in more and more related environments, managing information high quality throughout distributed programs, and addressing workforce expertise gaps.

One other persistent problem is governance, clearly defining accountability when automated programs work together with bodily belongings. Addressing these points can be crucial to making sure that automation and digitalization enhance resilience and security, not simply effectivity.

The publish Mitsubishi Electrical follows digital-first technique for superior air mobility appeared first on The Robotic Report.