Nowaste Logistics, a Swedish third-party logistics (TPL) supplier, has ordered a second robotic selecting cell from Cognibotics following the profitable pilot of the primary set up.

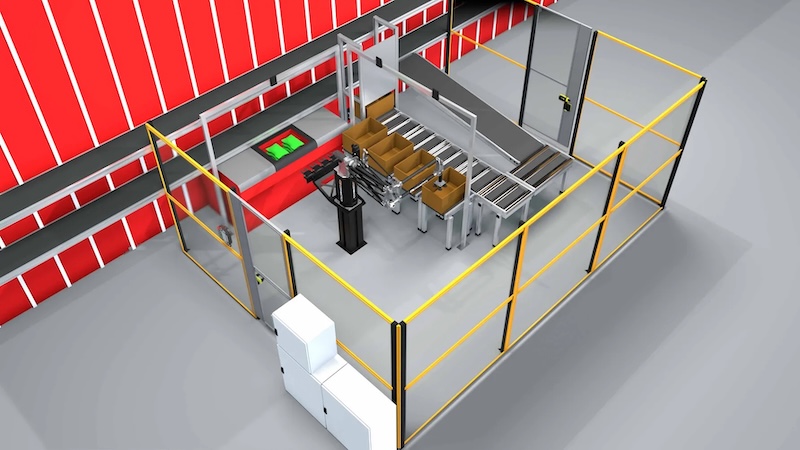

Built-in with Nowaste’s AutoStore system delivered by Swisslog, the Cognibotics robotic cell performs high-speed selecting instantly from AutoStore ports, enabling Nowaste to scale with better operational robustness and a future-proof method to automated order success, strengthening its business providing to TPL clients.

The Cognibotics material-handling robotic, geared up with Sics.AI’s imaginative and prescient system, has been working in manufacturing at Nowaste with steady efficiency and dependable uptime.

Primarily based on these outcomes, Nowaste is now increasing robotized selecting as a strategic element of its warehouse operations.

Patrik Johnfors, head of implementation and resolution design at Nowaste Logistics, says: “The primary cell proved what we wanted to know – that robotized selecting can deal with a various product assortment and nonetheless ship the robustness and stability our TPL operations require.

“A second cell is a transparent strategic step for us, making our warehouses extra resilient to seasonal peaks and higher positioned to future-proof operations as buyer calls for evolve.”

Scaling capability with high-speed, long-reach selecting

For TPL suppliers, this selecting cell validates that attain and velocity are key to delivering excessive, steady selecting capability, enabling a number of displays, totes, and hand-off factors to be positioned inside attain.

This helps versatile format design, environment friendly batching, and easy dealing with of combined product flows. Capability scales naturally as buyer wants evolve, permitting warehouses so as to add robotic cells with out reconfiguring present infrastructure.

,” stated Fredrik Malmgren, CEO of Cognibotics, says: “Nowaste is a powerful instance of how a contemporary TPL supplier makes use of robotization to strengthen its operations – the place robustness, capability, and format flexibility are key.

“This second order can also be an necessary milestone for us; it marks the primary time our software program automation basis Juliet & Romeo is working in full manufacturing on a material-handling robotic cell, proving that our software-defined movement is able to scale throughout real-world logistics environments.”

Software program-defined movement and AI imaginative and prescient for real-world logistics

Within the AutoStore setup, the Nowaste selecting cell brings collectively Cognibotics’ high-speed, long-reach robotic with a sophisticated AI imaginative and prescient system able to dealing with a extremely numerous product combine.

Powered by Cognibotics’ automation basis Juliet & Romeo, the cell manages real-time robotic movement, gripping, and conveyor hand-off whereas simplifying integration with Nowaste’s warehouse administration and management methods.

Through the use of a software-defined movement platform, Cognibotics permits Nowaste to adapt layouts, product flows, and merchandise varieties over time with out {hardware} redesign, an important functionality for TPL suppliers serving a number of clients with evolving wants.