R3 Robotics (previously Circu Li-ion) has introduced €20 million in mixed financing to industrialize automated disassembly of electrical car techniques at scale.

The corporate has raised €14 million in Sequence A funding, co-led by HG Ventures and Suma Capital, with participation from Oetker Assortment KG, the European Innovation Council Fund (EIC Fund), and present shareholders together with BonVenture, FlixFounders, and EIT City Mobility, alongside €6 million in European grants.

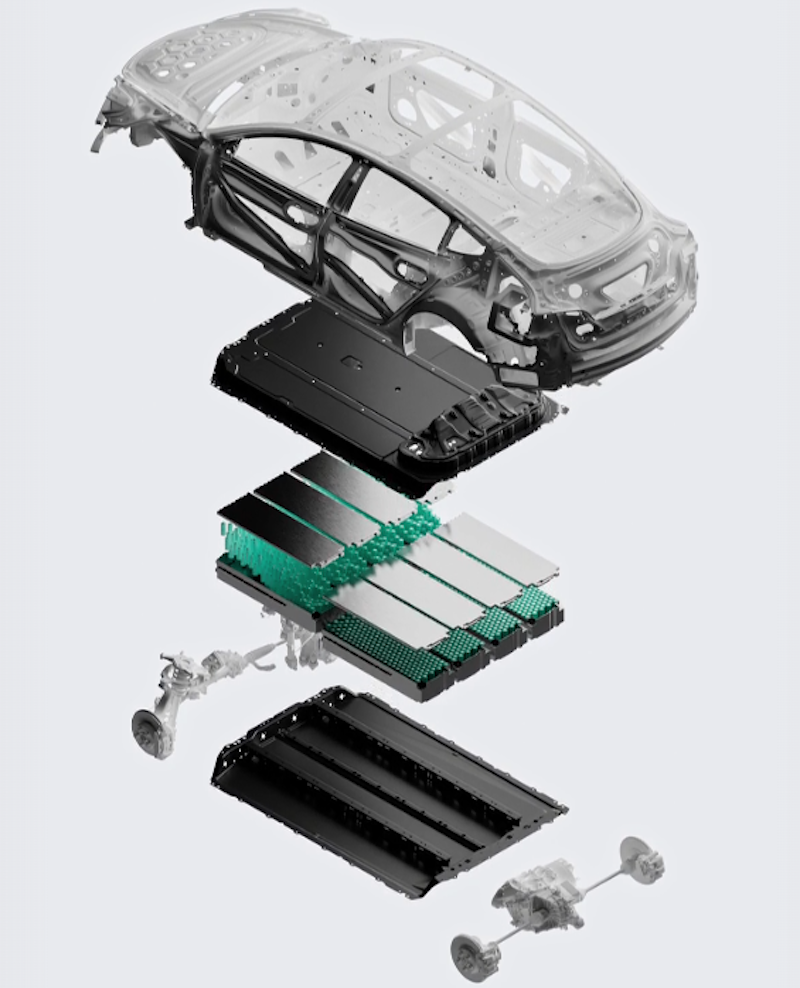

The funding coincides with the corporate’s rebranding from Circu Li-ion to R3 Robotics and a transparent enlargement of scope: from battery disassembly to automated dismantling of full electrical car techniques, together with e-drives, energy electronics, and different high-value elements.

The long-term ambition is to allow absolutely automated disassembly throughout total car techniques. The brand new title displays the corporate’s industrial focus – Restore, Reuse, Recycle – powered by robotics.

Industrial disassembly at scale

As electrification accelerates throughout mobility and power techniques, end-of-life volumes of advanced electrified elements are anticipated to extend sharply. Handbook disassembly stays labor-intensive, expensive, and troublesome to scale safely.

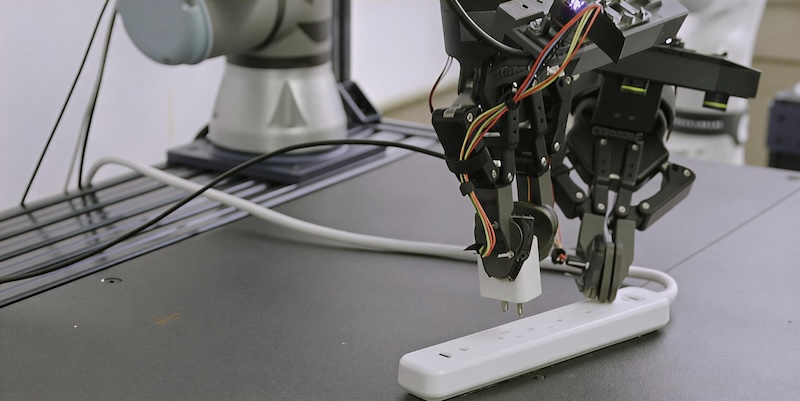

R3 Robotics addresses this problem with a dismantling platform designed for repeatable, high-throughput operation in steady industrial environments.

European coverage reinforces this shift. The Vital Uncooked Supplies Act underscores the necessity to strengthen safe and resilient home provide chains for strategic supplies.

In parallel, the EU Battery Regulation introduces progressively stricter recycling effectivity targets, together with a 70 % goal for lithium-based batteries by 2030, alongside materials restoration and recycled content material necessities.

Along with the Finish-of-Life Autos Directive, these frameworks are reshaping industrial recycling infrastructure.

“The bottleneck isn’t recycling expertise; it’s clear feedstock, which means getting advanced electrified techniques safely and cost-effectively dismantled at an industrial scale,” stated Antoine Welter, CEO and co-founder of R3 Robotics.

“We’re constructing a dismantling platform that turns end-of-life techniques right into a strategic supply of essential supplies and reusable elements for superior industrial economies.”

R3 Robotics expertise

R3 Robotics’ dismantling platform combines pc imaginative and prescient, AI, and specialised robotic tooling to automate the disassembly of lithium-ion battery packs, e-motors, energy electronics, and different high-value electrified elements.

The system minimizes human publicity to high-voltage hazards and delivers the associated fee construction and reliability required for industrial-scale operations.

The corporate is working with Fortum Battery Recycling, a serious built-in battery recycler lively throughout a number of levels of the European battery recycling worth chain, from assortment and pre-treatment to materials refining, to deploy its automated dismantling expertise at industrial scale.

Past its work with recycling companions, R3 Robotics works instantly with automotive OEM prospects, processing end-of-life battery techniques via its centralized dismantling infrastructure to get well essential uncooked supplies and assist safe sourcing.

“R3 Robotics is addressing a essential industrial bottleneck within the provide of strategic uncooked supplies,” stated John Glushik at HG Ventures. “Scalable dismantling infrastructure is important to strengthen resilience and safe entry to essential inputs.”

Lighthouse facility and strategic markets

The announcement marks the enlargement of R3’s lighthouse disassembly facility in Karlsruhe, Germany, designed to display industrial-scale efficiency and function a reference website.

R3 Robotics views Germany and France as key European markets, given their robust automotive and industrial ecosystems, electrification momentum, and focus of recycling and remanufacturing companions.

“R3 Robotics combines robust industrial execution with a scalable method to dismantling advanced electrified techniques,” stated Natalia Ruiz, Accomplice at Suma Capital. “This functionality is essential to unlocking supplies and elements at scale.”

Deployment and development technique

The Sequence A financing and extra European grants will assist:

- Expertise and workforce enlargement: Strategic hiring throughout engineering, AI, software program, and operations

- European market scale-up: System deployments with industrial recyclers and automotive companions

- Facility scale-up: Elevated capability in Karlsruhe and Luxembourg

- US market entry: Industrial preparations and strategic partnerships for roll-out in 2026

To additional strengthen its strategic improvement, R3 Robotics has added Peter Mohnen, former CEO of KUKA, to its advisory board.

“Automated disassembly at this stage of complexity represents one of many hardest challenges in industrial robotics: managing variability, security, and throughput concurrently,” stated Peter Mohnen, former CEO of Kuka and board member of R3 Robotics.

“R3’s method demonstrates the depth of automation experience required to make this work at scale.”