By Ulrich Schäfer, undertaking engineer, Zasche Handling

Producers at this time are navigating an more and more complicated balancing act. Excessive-mix manufacturing, persistent labour shortages, and stricter security and ergonomic requirements are stretching each operators and processes.

Handbook dealing with can now not maintain tempo with out risking fatigue or harm, but absolutely robotic techniques are sometimes inflexible, expensive, and onerous to adapt to altering half varieties. Between these extremes lies a rising alternative for options that mix human experience with focused automation.

Semi-automated bin selecting sits squarely on this center floor. It presents a sensible various when full automation would require disproportionate funding, but guide lifting and dealing with exceed what’s secure or sustainable over time.

Somewhat than eliminating human involvement, this strategy preserves operator judgment the place it issues most, whereas shifting the bodily burden of dealing with to techniques designed for consistency and endurance.

Reframing bin selecting: Shared work, shared energy

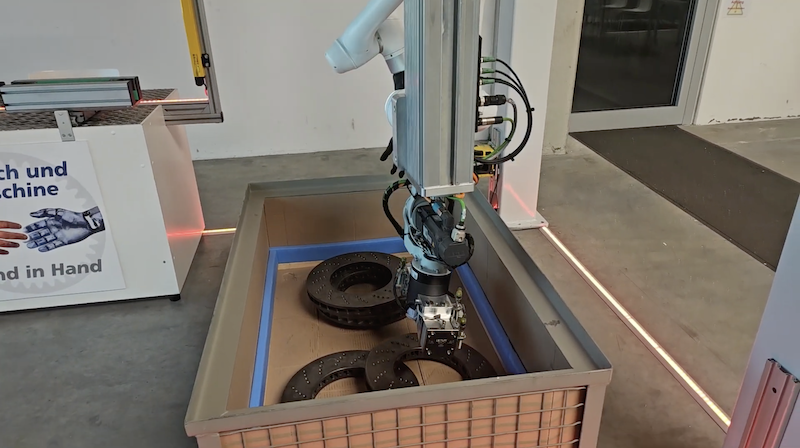

Elements could be picked immediately from disordered containers, with the system figuring out every half’s place and adjusting the gripper accordingly.Discussions round bin selecting have lengthy been dominated by robotics. In lots of real-world functions, nevertheless, the purpose is to not substitute the operator however to assist them.

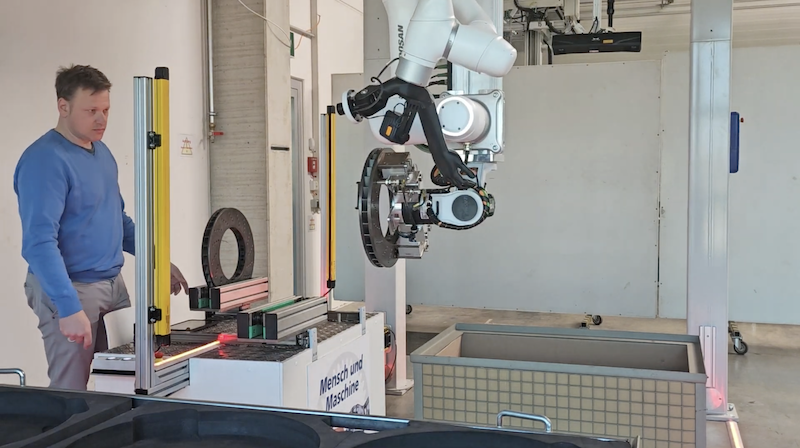

Semi-automated bin selecting reframes the duty as a collaborative course of, a dynamic that’s simpler to understand when seen in operation (a brief demonstration video illustrates this interplay).

Power-intensive actions are dealt with mechanically, whereas operators stay liable for work that calls for dexterity, timing, and situational consciousness. The result’s a division of labour formed by the respective strengths of people and machines.

This hybrid mannequin addresses the restrictions on each ends of the automation spectrum. It alleviates the bodily pressure inherent in guide work, whereas avoiding the rigidity of absolutely automated cells that usually require intensive reprogramming when components or processes change.

As a result of these techniques are simpler to regulate and redeploy, they aren’t confined to large-scale operations alone. Smaller producers may undertake semi-automation as a means to enhance security and productiveness with out committing to disruptive infrastructure overhauls.

Crucially, this flexibility additionally extends to how components are offered. Elements don’t must be exactly organized prematurely, and in lots of instances, complicated or purpose-built containers could be averted altogether – decreasing upstream dealing with effort and pointless price.

Why human-centric automation delivers extra

Parallel workflows in motion: guide processing on the operator station whereas the system retrieves the subsequent element behind an outlined security boundary.

What distinguishes semi-automated dealing with from typical robotic setups is its emphasis on holding operators actively engaged within the course of.

Human experience stays central, whereas automation offers the energy, stability, and repeatability wanted to handle demanding dealing with duties. This steadiness creates a workflow through which folks information the method and expertise reinforces it.

On the manufacturing facility flooring, this collaboration interprets into tangible advantages. By relieving operators of probably the most bodily taxing motions, they’re free to focus on precision, coordination, and real-time decision-making.

Accuracy improves, fatigue is lowered, and work turns into extra sustainable over lengthy shifts – with out sacrificing management or responsiveness.

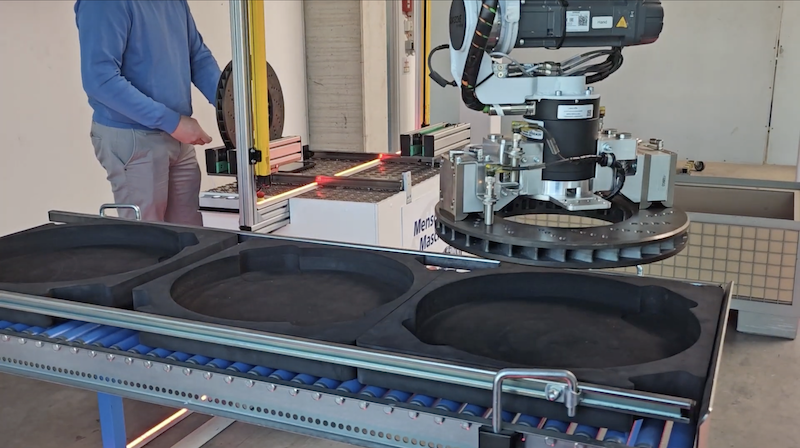

On the similar time, these techniques permit energy and finesse to coexist. Semi-automated platforms ship lifting functionality and movement management that guide dealing with can not obtain reliably, whereas nonetheless leaving remaining positioning and adjustment in human palms.

This mixture enhances each security and consistency, notably in functions the place delicate placement issues as a lot as load capability.

As soon as the operator has accomplished the guide process (for instance, inspection, meeting preparation), semi-automatic options can assist managed placement into the subsequent stage of the method.

Adaptability additional strengthens the case. Versatile grippers, modular end-effectors, and intuitive management interfaces permit groups to accommodate new components, layouts, or batch sizes with minimal disruption.

Operators can work together with semi-automated setups by way of sensors, easy push-button controls, or tablet-based changes relying on process complexity.

In environments the place parts arrive in combined or disordered containers, built-in sensing and orientation assist assist keep effectivity – with out forcing the encompassing course of to evolve to the automation.

Taken collectively, these attributes – collaboration, functionality, and adaptableness – show why human-centric techniques stay a practical path ahead.

They elevate the work folks do finest whereas assigning bodily demanding or repetitive duties to machines, leading to operations which are safer, extra versatile, and higher aligned with real-world manufacturing situations.

Sensible progress, not grand overhauls

Throughout trade, there’s a rising recognition that “smarter” doesn’t at all times imply “absolutely automated”. A lot of at this time’s handiest enhancements come not from changing processes fully, however from strengthening them in focused, significant methods.

Semi-automated bin selecting exemplifies this mindset: enhancing security, elevating effectivity, and preserving flexibility with out imposing inflexible workflows.

Extra importantly, it reinforces a perspective that usually will get misplaced within the automation narrative. Progress doesn’t must be disruptive to be transformative.

When techniques are designed to enhance human functionality relatively than constrain it, the mix of machine energy and human judgment turns into a strategic benefit – one which producers of all sizes can apply.

As industrial environments proceed to evolve, the query is now not whether or not automation ought to substitute folks. The extra compelling query is how expertise can prolong what folks do finest whereas releasing them from duties that machines are higher suited to deal with.

Semi-automated bin selecting presents a compelling reply – and a glimpse of how human talent and clever help can function not in competitors, however in live performance.