The HMND 01 wheeled, two-armed robotic picks up a tote. Supply: Humanoid

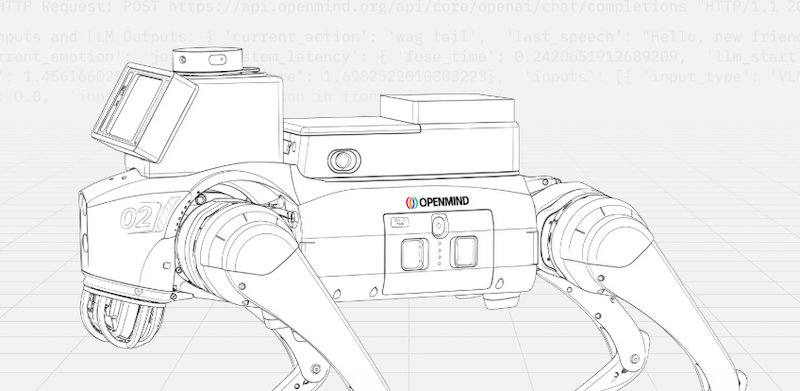

Humanoid and Siemens AG yesterday stated that they’ve accomplished a proof of idea, or POC, demonstrating using a cellular manipulator in industrial logistics. The POC concerned Humanoid’s HMND 01 wheeled Alpha robotic. The corporate deployed the robotic in precise operations at a Siemens facility.

Humanoid, which is formally often known as SKL Robotics Ltd., structured the POC in two phases. The primary section targeted on in-house improvement and demonstration. The corporate stated its workforce constructed a “bodily twin” to assist testing, optimization, and speedy iteration.

Within the POC, the HMND 01 Alpha performed a tote-to-conveyor de-stacking job inside Siemens’ logistics course of. The cellular manipulator autonomously picked totes from a storage stack, transported them to a conveyor, and positioned them on the designated pickup level for human operators.

The system repeated this sequence till the stack was absolutely empty, which demonstrated how robots can tackle repetitive logistics duties, Humanoid stated.

The second section included a two-week on-site deployment on the Siemens Electronics Manufacturing facility in Erlangen, Germany, the place the corporate assessed the robots in a real-world manufacturing atmosphere.

HMND 01 meets metrics for fulfillment at Siemens

Humanoid stated the POC measured each the efficiency and reliability of its robots beneath autonomous operation. They met all goal metrics, together with a throughput of 60 tote strikes per hour, operation with two totally different tote sizes, steady autonomous job execution for greater than half-hour, and uptime exceeding 8 hours.

The companions additionally evaluated the undertaking utilizing the general pick-and-place success charge and the autonomous pick-and-place success charge, which had been each above 90%.

Humanoid and Siemens stated this POC is a primary step towards a long-term strategic collaboration. The businesses added that they’re open to increasing the scope and including use circumstances. The companions additionally could progress towards a broader rollout, deploying a higher variety of robots throughout Siemens’ services, based mostly on the robotic’s particular ability set.

“As Siemens’ ‘Buyer 0,’ the Electronics Manufacturing facility Erlangen is happy to companion with the Humanoid workforce,” stated Stephan Schlauss, world head of producing movement management at Siemens. “We’re tackling manufacturing automation, discovering new alternatives for Siemens, and are wanting to advance this promising know-how throughout our manufacturing facility community to ship buyer worth.”

Humanoid plans to deploy its robots in additional settings

“At Humanoid, we’re a commercially pushed firm. Our focus is on creating robots that ship measurable worth in real-world settings,” said Artem Sokolov, founder and CEO of Humanoid. “Working carefully with industrial and know-how companions permits us to validate our methods towards actual operational necessities and perceive which use circumstances matter outdoors the lab.”

“This joint POC with Siemens confirmed clear potential for sensible deployment of cellular manipulator robots,” he added. “We see them transfer steadily towards the true world, and partnerships like this one assist speed up that transition.”

Humanoid this week additionally partnered with movement know-how supplier Schaeffler Applied sciences AG. Over the subsequent 5 years, the businesses agreed to carry a whole bunch of Humanoid’s robots into Schaeffler’s manufacturing services.

The submit Humanoid and Siemens proof of idea exhibits the way in which to industrial deployments appeared first on The Robotic Report.