Reaching web zero emissions by 2050 and bettering competitiveness by lowering manufacturing prices is the twin goal set by the aeronautical business.

This purpose is at the moment hampered by the dependence on heavy, costly, and rigid equipment in manufacturing processes.

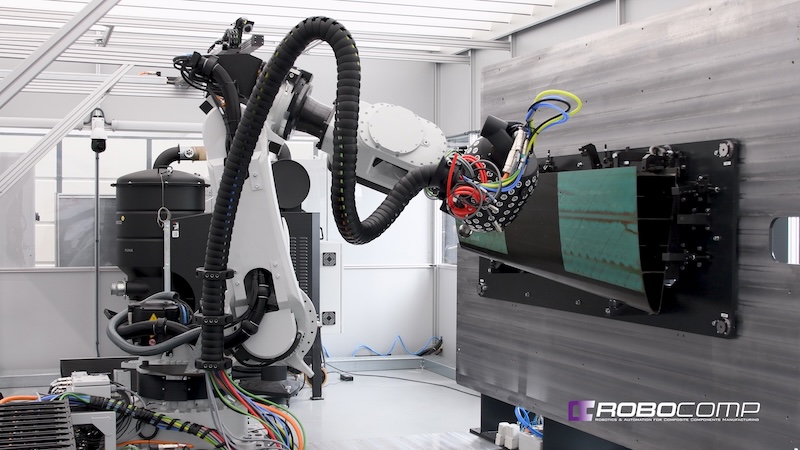

To deal with this case, the expertise centre IDEKO has contributed to the event of a brand new technology of versatile, sensorised and linked robotic cells throughout the framework of the ROBOCOMP mission.

Led by the DANOBAT cooperative, this initiative goals to rework the manufacturing processes of aeronautical elements.

“The brand new options are designed to exchange conventional programs and automate crucial machining operations on carbon fibre elements, similar to milling, drilling and trimming, in an effort to enhance effectivity and cut back power consumption,” explains the centre’s researcher, Asier Barrios.

This technological transition responds to particular operational limitations of present equipment. Whereas giant conventional gear often machines elements in a horizontal place, limiting entry to many elements with advanced geometries, ROBOCOMP’s proposal introduces the flexibility to work on elements positioned vertically.

This characteristic additionally facilitates manufacturing scalability, permitting vegetation to adapt shortly to new manufacturing necessities.

Precision and monitoring

The contribution of the expertise centre, a member of the Basque Analysis and Expertise Alliance (BRTA), has been important in offering intelligence to those new options.

Particularly, IDEKO’s scientific work has centered on growing robotic precision by way of enhancements in mechatronics and system calibration, a crucial consider assembly the strict necessities of the aerospace sector.

As well as, the centre has geared up these cells with the intelligence required to function autonomously. Via synthetic imaginative and prescient programs and sensors, the robots are capable of see and analyse the standing of the manufacturing course of because it takes place.

This digitalisation permits the method to be monitored in actual time, immediately figuring out potential errors or deviations to make sure the standard of the half.

Sustainability has additionally been addressed throughout the initiative, by way of the implementation of applied sciences that optimise the machining of composite supplies to make sure extra environment friendly use of power and assets.

Switch to different sectors

The success of the initiative has been supported by a strong industrial consortium masking all the worth chain.

Alongside the management of DANOBAT and the scientific data of IDEKO, the mission has benefited from the participation of Airbus, which has contributed the top person’s imaginative and prescient and necessities; Robotnik, a European chief in cell robotics; and Industrial Olmar, an organization devoted to the manufacture of autoclaves and stress gear.

This collaboration has enabled the event of applied sciences that place the Basque and Spanish industrial cloth on the forefront of superior manufacturing, with a transparent drive in the direction of different markets.

The applied sciences developed at ROBOCOMP shall be transferable to different machining-intensive sectors, similar to automotive, power and capital items, thereby strengthening the competitiveness of small and medium-sized enterprises and opening up new enterprise alternatives within the discipline of superior providers and good upkeep.

The mission has been funded by the Centre for the Growth of Industrial Expertise (CDTI) by way of the Aeronautical Expertise Programme (PTA), a grant framed throughout the Restoration, Transformation and Resilience Plan of the Authorities of Spain.