Gantry methods utilizing ServoBelt know-how can present the automotive business with flexibility at a fraction of the price of rack-and-pinion methods. Supply: Bell-Everman

Overhead pick-and-place gantries are an necessary a part of trendy automotive vegetation, transferring and positioning components with the pace, precision, and reliability that high-volume manufacturing calls for. Historically, producers have confronted an equipment-selection dilemma, with the business dominated by heavy-duty methods constructed from huge metal fabrications. Designed for excessive payloads, these overbuilt methods come from massive gear suppliers who provide strong engineering at a premium value, prolonged lead instances and restricted room for personalisation.

Small and midsize automotive functions, nevertheless, don’t require such excessive capabilities, and in these circumstances, the outsized methods signify a vital mismatch. Compounding this problem, the business’s fast-moving manufacturing atmosphere calls for suppliers who can adapt shortly, customise gantry methods to particular software wants and ship inside aggressive time frames — necessities that many massive, established gear producers are unable to satisfy.

Happily, a movement management system has emerged to fill this hole. Gantry methods that includes ServoBelt technology ship the industrial-grade sturdiness and customizability automotive manufacturing requires — at a fraction of the price of conventional rack-and-pinion methods and with lead instances which are typically lower than half of these of bigger suppliers.

Equally necessary, superior beam engineering using T-slot extrusions ensures ServoBelt methods meet the structural efficiency requirements producers anticipate from conventional rack and pinion gear.

For these causes, ServoBelt movement management know-how allows automotive producers to implement superior overhead automation with out compromising on the efficiency their manufacturing calls for.

Designing an overhead gantry for an automotive provider

Progressive Machine & Design (PMD), a {custom} automation firm in Victor, N.Y., was tasked with designing an automatic manufacturing line for a Tier 1 automotive provider. A part of a diesel engine camshaft manufacturing operation, the road would come with a pick-and-place gantry system to move components by means of a number of machining operations.

The manufacturing line consisted of sequential machining operations, with 4 to 5 machines at every stage. The gantry’s perform was to deal with the camshafts, from uncooked inventory to closing product, transporting them between the varied machining facilities.

The system was designed to select up the uncooked camshaft blanks and ship them to the primary set of machines. From there, it will transfer the components by means of completely different operations, together with grinding, lathing, and different machining processes. The gantry was designed to interface with the top-loading machining facilities and to exist above the machines, saving priceless ground area.

The core problem throughout the design course of was to engineer a strong overhead gantry system that would navigate a good plant format, deal with a two-camshaft payload weighing roughly 80 kg (176.3 lb.), and supply exact positioning for half supply into the machines.

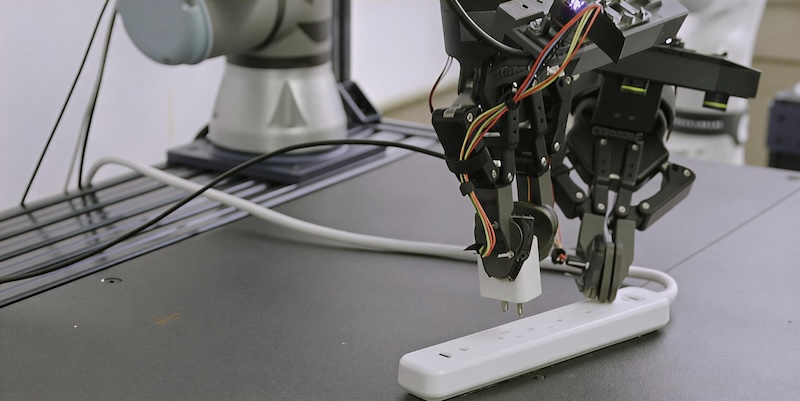

Gantry-based robotics can transport supplies throughout manufacturing processes. Supply: Bell-Everman

ServoBelt drive delivers efficiency

For its gantry system, PMD included ServoBelt know-how — a linear drive system that mixes the reliable “rack and pinion” drive methodology with precision and anti-backlash traits because of a singular belt design. ServoBelt’s key options, corresponding to its ease of customization, excessive efficiency, and avoidance of overly greased metal racks, made it an acceptable alternative for this challenge.

Design flexibility and customization: Not like inflexible, standardized methods, ServoBelt know-how allowed PMD to customise the gantry’s dimension, top, and beam span to suit the precise plant format constraints.

This flexibility was a vital issue that “tipped the scales” in ServoBelt’s favor, in accordance with Brent Stratton, chief mechanical engineer at PMD.

Excessive efficiency with out over-engineering: ServoBelt delivered the required efficiency specs with out pointless over-engineering. Although able to even tighter precision, it offered the required quarter-millimeter positioning accuracy and will deal with high-speed journey, working at 3 m/s (6.7 mph) — effectively inside its functionality of 4 m/s (8.9 mph).

Lengthy-distance capabilities: A key benefit of ServoBelt is its distinctive belt-rack design, which eliminates belt stretch over any journey distance. This characteristic allowed PMD to create an extended gantry that spanned a number of machining facilities with out sacrificing positioning accuracy.

“Whereas we don’t typically make methods this lengthy, we’d normally attain for a continuous-loop or OMEGA-type drive,” Stratton mentioned. “However the great thing about the ServoBelt belt-rack system is that it takes all of the stretch out of the equation. You possibly can go actually lengthy with out worrying about belt stretch in any respect.”

Future scalability: The modular nature of ServoBelt know-how helps future enlargement. If the operation ultimately requires extra machines, for instance, the gantry may be prolonged to accommodate the expanded format, offering a long-term and adaptable resolution.

ServoBelt has a design to eradicate belt stretch over any journey distance. Supply: Bell-Everman

Composite beam meets the business’s structural requirements

Whereas ServoBelt offered the movement management know-how, its beam design represented an equally vital engineering problem. Automotive producers used to conventional rack-and-pinion methods have particular expectations relating to structural efficiency.

Composite aluminum beam provides structural efficiency. Supply: Bell-Everman

To satisfy these necessities, the Bell-Everman engineering crew carried out in depth “beam science” work. It analyzed and optimized a number of structural traits like beam stiffness, deflection, torsional stiffness, torsional deflection, and space second of inertia. Every parameter performs an necessary function in making certain the gantry maintains positioning below load and all through its journey vary.

Not like Bell-Everman’s conventional single-piece extrusion designs, this software required a brand new composite-beam building to realize the required structural efficiency. The engineers designed a beam meeting utilizing versatile T-slot extrusions skinned in anodized aluminum, making a construction that eradicated deflection between mounting factors.

This composite strategy delivered a number of advantages. It offered the structural rigidity required for the appliance, provided the aesthetic look of premium industrial gear and maintained the customizability that made ServoBelt enticing within the first place.

As well as, the in depth design and testing work proved that the gantry system may meet the identical structural requirements as heavy-duty metal gear whereas sustaining price and lead time benefits.

Customized enhancements guarantee security and reliability

Along with the core gantry and beam, PMD designed and built-in a number of {custom} options to make sure the pick-and-place system operated safely and reliably. The controls included Allen Bradley drives and motors with Neugart gearboxes.

To deal with the payload, PMD chosen Schunk grippers with a security lock characteristic that forestalls them from opening if air strain is misplaced. Engineers additionally designed a small Y-axis shift into the gripper design to accommodate minor positional misalignments of the machines.

For security, PMD carried out a danger evaluation. After figuring out the necessity for redundant Z-axis brakes, engineers tasked Bell-Everman with integrating these brakes into the gantry’s design. The corporate’s engineers offered a clear design for the mixing of those brakes. The system’s drives additionally featured Protected Torque Off (STO) to satisfy security necessities.

To deal with the difficulty of oily components and dripping coolant, PMD designed a collection of drip trays, which served two functions: They stored coolant contained and prevented employees’ palms from getting into the gantry’s transferring components. Bell-Everman delivered the gantry with a bolt sample to facilitate the mixing of those custom-designed trays.

The ServoBelt-powered gantry robotic can enhance security and effectivity. Supply: Bell-Everman

Outcomes: Excessive-end automation at a decrease price

The ServoBelt-powered gantry system efficiently automated the camshaft transport course of, integrating seamlessly with the prevailing machining facilities and the client’s manufacturing execution methods (MES) database.

- Operational success: The gantry system now handles the whole camshaft workflow, from the preliminary uncooked clean to the ultimate floor unit.

- Security and reliability: The gantry consists of many security enhancements, together with {custom} drip trays to include coolant and redundant brakes on the Z-axis. The gantry’s strong building and low upkeep necessities additionally guarantee long-term reliability.

- Value-effectiveness: By offering high-end linear motor efficiency at a considerably decrease price, ServoBelt know-how has enabled the implementation of superior automation with out the value tag of over-engineered methods.

The ServoBelt-powered gantry now delivers the exact, high-speed automation the provider wanted whereas maintaining prices below management. It additionally fills a vital hole out there, offering producers with a high-performing various to outsized methods for small to midsize payload functions that beforehand would have required defaulting to massive, heavy-duty gear.

“What made this challenge work was our collaborative strategy with Bell-Everman and their means to satisfy our distinctive requests — that’s what received us over,” defined Stratton. “Even past simply assembly our instant necessities, collectively we constructed one thing that would adapt and increase as wants change.”

In regards to the creator

In regards to the creator

Parker Maccianti is lead mechanical engineer at Bell-Everman and has been with the corporate for 9 years. He has a Bachelor of Science in Mechanical Engineering from UC Irvine.

This text is posted with permission.

The put up ServoBelt provides high-end efficiency for automotive gantry appeared first on The Robotic Report.