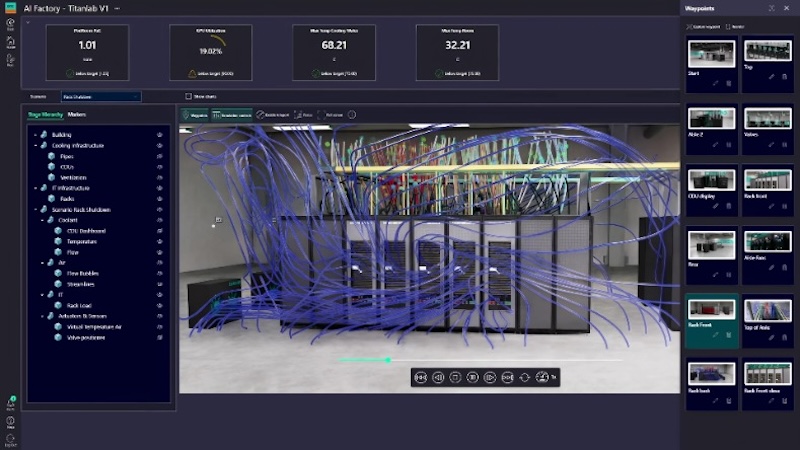

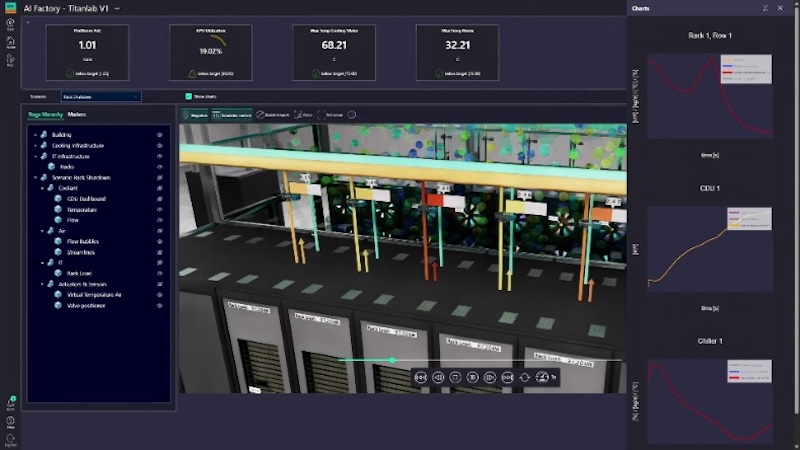

Siemens has launched Digital Twin Composer, a brand new software program answer that builds industrial metaverse environments at scale, empowering organizations to use industrial AI, simulation and real-time bodily information to make choices nearly, at pace and at scale.

Digital Twin Composer allows industrial firms to mix 2D and 3D digital twin information from Siemens’ complete digital twin with bodily real-time info in a managed, safe real-time photorealistic visible scene, constructed utilizing Nvidia Omniverse libraries.

With Digital Twin Composer, firms can quickly construct and preserve this world surroundings, containing all facets of their product or manufacturing information (each digital and bodily) in a safe, managed high-fidelity 3D expertise, all through the lifecycle of the product, course of or facility.

Digital Twin Composer gives contextualized, real-time insights and intelligence enabling firms to visualise, work together with and iterate on any product, course of or manufacturing unit in its real-world context earlier than bodily design or development – whether or not it’s a brand new smartphone, a tanker in a shipyard, an autonomous electrical car, or a brand new AI manufacturing unit on a greenfield or brownfield website.

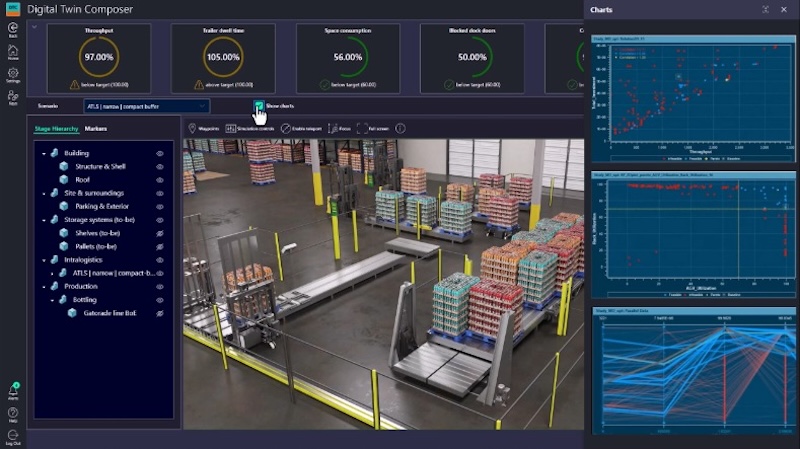

PepsiCo and Siemens are digitally reworking choose US manufacturing and warehouse amenities by changing them into high-fidelity 3D digital twins that simulate plant operations and the end-to-end provide chain to ascertain a efficiency baseline.

Inside weeks, groups optimized and validated new configurations to spice up capability and throughput, giving PepsiCo a unified, real-time view of operations with flexibility to combine AI-driven capabilities over time.

Leveraging Siemens’ Digital Twin Composer, Nvidia Omniverse and laptop imaginative and prescient, PepsiCo can now recreate each machine, conveyor, pallet route and operator path with physics-level accuracy, enabling AI brokers to simulate, take a look at and refine system modifications – figuring out as much as 90 p.c of potential points earlier than any bodily modifications happen.

This method has already delivered a 20 p.c enhance in throughput on preliminary deployment and is driving quicker design cycles, practically 100% design validation and 10 to fifteen p.c reductions in capital expenditure (Capex) by uncovering hidden capability and validating investments in a digital surroundings.

Many design, engineering and manufacturing groups nonetheless work independently, every counting on totally different instruments and disconnected information methods.

Digital Twin Composer reduces these obstacles by unifying design, simulation and operations into one residing and contextualized mannequin that empowers engineers to check merchandise, processes and amenities in minutes, validate automation lengthy earlier than {hardware} exists and function the actual product or facility from one digital twin.

Joe Bohman, govt vp, PLM Merchandise, Siemens Digital Industries Software program, says: “The brand new Digital Twin Composer delivers on our imaginative and prescient for the economic metaverse. It helps producers to beat the unprecedented challenges of mastering complexity, accelerating manufacturing, decreasing prices and rising profitability.

“Siemens and Nvidia are partnering to assist producers carry essentially the most complicated merchandise, processes and factories on-line quicker, increase resiliency and sustainability, and repeatedly optimize efficiency.”

Rev Lebaredian, vp of Omniverse and Simulation Know-how, Nvidia, says: “In an period the place each bodily object and course of could have a digital twin, Siemens’ Digital Twin Composer establishes a digital thread that connects the silos of design, engineering, and operations throughout the Siemens Xcelerator ecosystem.

“By integrating Nvidia Omniverse libraries into Digital Twin Composer, enterprises can benefit from bodily correct simulation throughout their workflows to validate their total lifecycle – from product design to manufacturing unit logistics – within the digital world earlier than committing a single atom to the actual one.”

Digital Twin Composer is a part of Siemens Xcelerator, an {industry} confirmed portfolio of software program utilized by firms worldwide to develop digital twins that empower them to design, simulate and put together their merchandise, course of and factories at pace and scale.

Digital Twin Composer is used to attach the excessive efficiency, photorealistic and bodily correct 3D digital twin created utilizing Siemens Xcelerator to real-world bodily information sources as such manufacturing execution software program (MES), high quality administration methods (QMS), programmable logic controller (PLC) code from a machine or manufacturing unit asset or industrial web of issues (IIoT) information – from throughout an open ecosystem of engineering information.

Additional insights could be realized by means of integration with Siemens’ industry-leading information science and AI software program, Rapidminer and different AI options to ship digital world intelligence and actual time insights to make choices in confidence.

Launched at CES 2026, Siemens’ Digital Twin Composer is at the moment in early entry with choose clients.

Major picture: Siemens’ Digital Twin Composer builds Industrial Metaverse environments at scale, empowering organizations to use industrial AI, simulation and real-time bodily information to make choices nearly, at pace and at scale