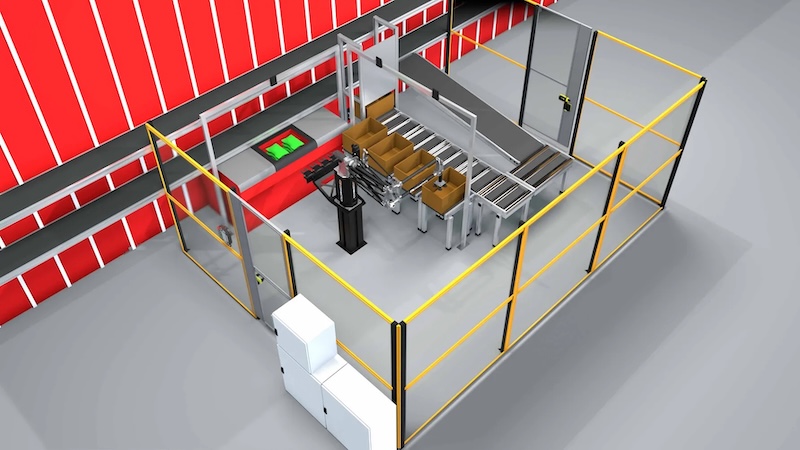

Bodily AI reminiscent of this force- and power-limited arm will get smarter because of math and collaboration, says a UR VP. Supply: Common Robots

The robotics {industry} is evolving quicker than ever, and the alerts of what’s subsequent are already seen. As somebody centered on shaping the way forward for automation, I see 4 developments that can redefine how bodily AI creates worth.

From smarter math and cooperative behaviors to industry-specific AI and a brand new information economic system, right here’s what I predict will matter most within the years forward.

1. Predictive math is a silent revolution for bodily AI

The following huge leap in robotics received’t come from {hardware}; it’ll come from math. Right now, robots are reactive: They reply to inputs and adapt in actual time. Tomorrow, they are going to anticipate.

Robots be taught duties reminiscent of meeting by way of demonstration and reinforcement studying. Supply: Common Robots

Rising mathematical strategies, reminiscent of twin numbers and jets, are quietly reshaping how we take into consideration modeling change. These instruments enable techniques to seize not simply what occurs when a robotic strikes, but in addition how these actions ripple by means of its total surroundings. Which means quicker optimization, richer state of affairs planning, and adaptive management that feels nearly intuitive.

Think about robots that would forecast the impression of a path adjustment earlier than executing it or simulate a number of “what-if” eventualities in milliseconds. This isn’t science fiction. It’s a pure evolution of how we compute derivatives and predict system habits. Whereas these strategies are nonetheless largely in analysis, their potential to rework robotics is simple.

In my opinion, predictive intelligence will outline the subsequent technology of automation. The query isn’t whether or not this shift will occur however how quickly and who will cleared the path.

2. Robots to go from solo to synergy

Imitation studying will turn out to be a defining functionality within the subsequent wave of automation. Right now, most robots function as unbiased models, managed by centralized fleet techniques or pre-programmed routines.

Tomorrow, they are going to be taught from one another and from people — some guided, some autonomous – forming adaptive groups that share behaviors and methods in actual time. This evolution builds on analysis the place robots not solely comply with a frontrunner’s trajectory but in addition observe, imitate, and refine actions collaboratively, enabling dynamic coordination with out inflexible scripts.

Industrial robotics distributors have laid the groundwork with fleet administration and synchronized movement for multi-arm techniques, however true peer-to-peer studying and self-organization are nonetheless rising. Nevertheless, I’m sure that in 2026, we’ll see actual deployments leveraging imitation-learned bodily AI fashions.

And the advantages are clear:

- Quicker configuration – and reconfiguration of workflows with out complicated programming

- Improved resilience when situations change unexpectedly

- Pure human-robot collaboration, the place robots intuitively comply with human intent or a grasp robotic’s tempo

As security requirements, inter-robot communication, and orchestration instruments mature, count on imitation-driven collaboration to maneuver from area of interest pilots into widespread adoption throughout factories and warehouses. This can rework robots from remoted models into cooperative, repeatedly studying groups.

Software program permits a number of robots to work collectively, however self-organization remains to be rising. Supply: Common Robots

3. Producers flip to purpose-built AI

Slightly than generic AI platforms, producers will more and more undertake task-specific AI constructed for a single course of like welding, sanding, inspection, or meeting. Anticipate AI welding, AI ending, AI meeting, and AI inspection to turn out to be commonplace options in new robotic cells, bringing automation to duties as soon as thought of too variable or complicated. These vertical functions will come out of the field pre-trained, pre-integrated, and able to ship measurable features from Day 1.

Welding is a flagship instance with AI-driven capabilities like vision-guided seam monitoring and machine learning-assisted parameter optimization already reworking the commerce of welding.

The following frontier contains is complicated, dexterous duties reminiscent of meeting, fastening, and complicated dealing with which have been historically proof against automation. In industrial settings, AI will allow robots to handle variability in elements and processes, whereas in service industries, comparable approaches will sort out duties like packaging, sorting, and even delicate materials dealing with.

Logistics can also be an {industry} the place we’ve seen nice developments, with AI-powered robotic techniques now demonstrating the power to carry out complicated choose, stow, and contact operations effectively and at scale.

In 2026, I anticipate we will even see investments spreading from logistics into retail. That is particularly thrilling, because it marks one other step in bringing robotic automation nearer to our every day lives, and retail is an {industry} I’ll monitor intently.

Siemens’ SIMATIC Robotic Choose AI, a pre-trained, deep learning-based imaginative and prescient software program, makes use of UR to automate duties for intralogistics know-how firm Mecalux. Supply: Common Robots

4. Knowledge from bodily AI is the brand new gasoline

The following huge shift received’t simply be in how robots transfer or suppose, it is going to be in how their information creates worth. Right now, many of the wealthy info robots generate — sensor readings, imaginative and prescient frames, drive profiles — stays on the sting, contained in the buyer’s website. That’s nice for privateness and velocity, but it surely means AI builders usually lack the real-world information they should construct smarter functions.

A UR8 Lengthy robotic arm in a Hirebotics welding cell. Supply: Common Robots

Sooner or later, I see robotic producers creating safe, opt-in information exchanges. With buyer consent and powerful privateness safeguards, anonymized efficiency information may very well be aggregated and supplied to AI builders as coaching units or mannequin companies.

Think about welding robots sharing de-identified seam high quality metrics, or sanding cobots contributing surface-finish information, fueling smarter AI for defect detection, predictive upkeep, and adaptive management.

The actual alternative lies in turning uncooked telemetry into structured, privacy-preserved insights that speed up innovation throughout the ecosystem. For producers, it means new income streams and steady enchancment of their very own robots.

For patrons, it means higher AI instruments educated on real-world situations, with out compromising confidentiality.

The outcome? A virtuous cycle the place each deployed robotic makes the subsequent technology smarter.

Elevated mission ROI: The payoff of predictive robotics

The way forward for robotics and bodily AI can be outlined by the interaction of superior strategies, smarter functions, and data-driven methods. Superior mathematical strategies will give robots the power to anticipate and adapt, making state of affairs planning quicker and extra exact.

Chief-follower coordination will flip remoted machines into cooperative groups that reconfigure workflows on the fly. Vertical AI functions, like AI welding and ending, will ship ready-to-use intelligence for particular duties, reducing rework and boosting high quality from Day 1. And a brand new information economic system will emerge, the place anonymized, privacy-preserved insights from deployed robots gasoline smarter AI fashions throughout the ecosystem.

Collectively, these shifts promise a step-change in mission ROI: greater productiveness per robotic hour, quicker deployment and reconfiguration, lowered downtime, and steady enchancment pushed by real-world information.

Concerning the creator

Concerning the creator

Anders Billesø Beck is vp, AI robotics merchandise, at Common Robots, the place he leads the worldwide AI product technique for the corporate’s collaborative robotic platform with a deal with innovation, adaptability, and the AI ecosystem. He’s well known as a pioneer in versatile and collaborative automation, with greater than 20 years of expertise advancing product improvement, new functions, and good manufacturing.

Beforehand at Universal Robots, Billesø Beck served as vp for know-how, guiding the event of cobot platforms, AI, security, and the UR+ developer ecosystem. He was additionally vp for technique and innovation, shaping the way forward for human-robot collaboration and next-generation UR merchandise.

Past his government duties, Billesø Beck is an energetic voice within the robotics neighborhood. He serves on the board of Odense Robotics, Denmark’s nationwide robotics cluster, and is a frequent speaker at international {industry} occasions, together with NVIDIA GTC, Automatica, Digital Tech Summit, and a number of podcasts.

The publish 4 bodily AI predictions for 2026 — and past, from UR appeared first on The Robotic Report.